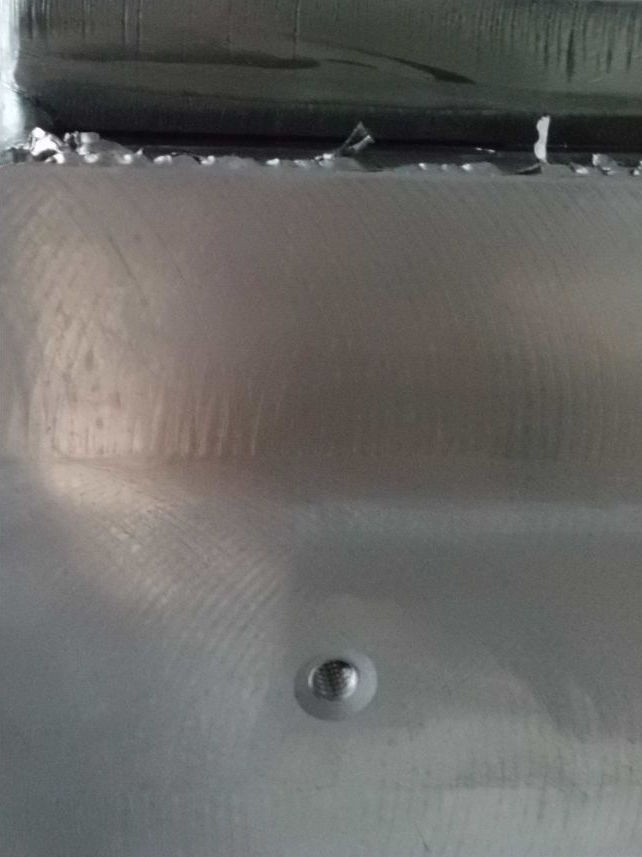

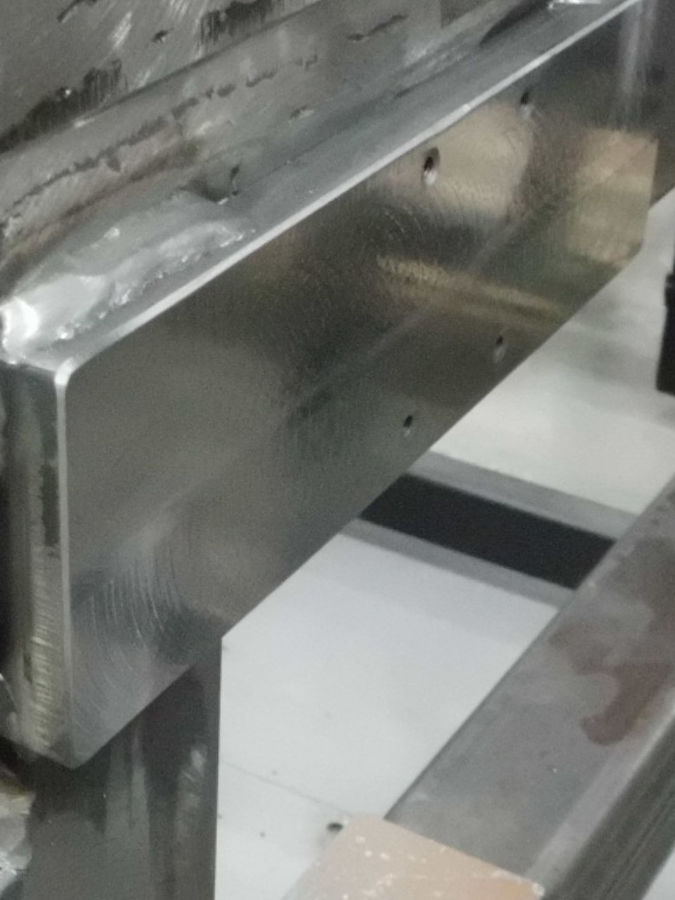

Most weldable steel types are not optimally suited for machining due to the alloy components. This means that when welded parts are milled over, a strong and tough burr is often produced.

Great effort with manual deburring

While burrs from free-cutting steel or cast materials can easily be removed with hand deburring machines, welded parts require more effort: In addition to larger machines, this also requires considerably more time. Thus, manual deburring of welded parts only makes sense for small quantities. For larger series, an automated solution is therefore required.

Challenges in automated deburring

Depending on the size and complexity, the dimensional tolerances on welded parts are usually several millimetres. In addition, there are often additional position differences during workpiece clamping for reworking. For reasons of efficiency, part machining and deburring should be carried out on one machine with the same clamping. Due to the dimensional or positional differences of the edges to be deburred, an appropriate solution is required. The good news: For several years now, deburring tools with deflectable spindles have been available for this purpose, which automatically compensate for the differences between the programmed and effective workpiece contour.

Process reliability is crucial

However, a prerequisite for an automated process is an absolutely reliable procedure. When deburring welded parts, increased demands are placed on the deburring tool. Depending on the machining direction, burrs of different thicknesses often appear on the same part. However, with appropriate tooling solutions and matching cutters, it is still possible to provide all edges with uniform deburring. When purchasing the deburring tool, it is therefore worthwhile to trust a competent supplier with the necessary experience in corresponding applications.

Do you have any questions on the subject of “Automated solutions for machining burrs on over-milled welded parts”? Contact us.

Advice and customer service

Roland Zahner

Technical Support / Distribution

Tel. +41 (0) 71 940 06 76

E-Mail: info@gravostar.com

Stay up to date

With the gravostar e-mail newsletter you will regularly learn everything about process-integrated part marking or automated deburring.