Dependability, customer orientation and efficiency – that is what we stand for at gravostar technologies

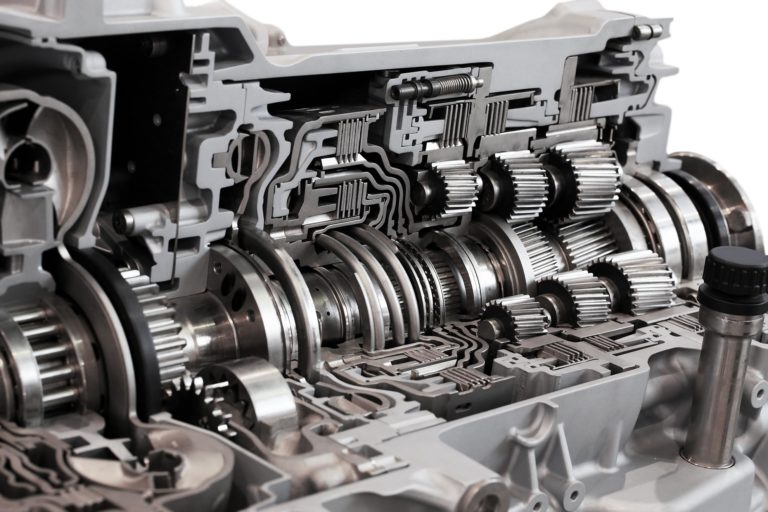

The right solution for every application

As a specialist in the areas of parts marking and deburring, we offer not only tools but also complete problem solutions. We guide and support our customers, starting with up-to-date inventory taking and the elaboration of tool proposals or possibly the development of custom solutions, right through their successful realisation in production.

This makes us a sought-after partner and a driving force. For all sectors in which it is necessary to reduce unnecessary working steps and therefore also error sources, for example in automotive and machinery construction, the aerospace sector, HGV and rail transport, etc. In short: gravostar has mastered the art of innovation. As an industry pioneer since 1999.