progress through courage and perseverance

Milestones of innovation

The pioneer has the courage to leave the well-trodden path. He is prepared to overcome long periods of hardship and even accept failure.

The reward: Collecting priceless experience and acquiring enormous know-how. This often leads to the status of innovation leader and undisputed expert. This is the path we are committed to – to always offer our customers the best possible solutions.

A deburring tool with axially spring-mounted electrospindle was developed for use in robots and special systems

As an option, the engraflexx ESP is now also available with automatic tool change unit

Various new and further developments were made in the area of stop milling cutters and special milling pins.

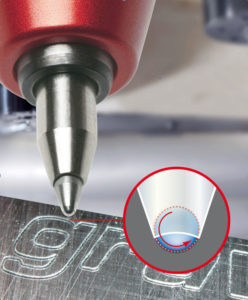

A pneumatically driven marking tool type with an integrated print setting. With the gravostar HRY- 20 PP the required marking depth can be precisely positioned on the tool and set with an accuracy between a few hundredths of a millimetre up to a few tenths of a millimetre.

A specific customer application was once again satisfied with the development and launch of the gravostar WSXP-20: the application of deep markings on un-machined castings plus the added requirement that the marking still had to be easily legible after painting.

Since that time a major customer who is a supplier to the automotive industry has purchased and is now using more than 10 engraflexx ESP deburring spindles with high frequency electric motor drives.

Based on the principle of the engraflexx LC, further versions have been developed: for deburring on rear, as well as front and rear edges of any undefined workpiece contours.

After a test period of more than two years the patent was granted for the axially deflectable engraflexx LC tool type

The axially spring-loaded engraflexx ELC deburring spindle was developed for use on robots and customised equipment as a supplement to the laterally deflectable spindle. The ELC version also has a high frequency spindle motor, the rotational speed of which can be controlled.

The engraflexx SX is a spindle with lateral deflection which can be fitted with any motor. When equipped with the corresponding adapter this spindle can also be used for special applications on CNC machines.

The development and market launch of the engraflexx LC series makes a further tool version available for the automatic solution of corresponding problems in deburring and final machining on CNC machines. An application was filed for the principle of this tool at the same time.

A micropercussion tool with integral pressure reduction to achieve a precisely adjustable marking depth was developed in the form of the gravostar WSRX-20 following an enquiry received from a power train manufacturer.

A patent was granted for the engraflexx EC deburring tool just under two years from the application for the patent and market launch.

After the previous premises became too small the company moved to Oberuzwil where the company had found an ideal site in a former shoe factory.

The world’s first deburring tool with spindle deflection driven directly from the machine spindle was launched in the form of the engraflexx EC. A genuine innovation for the deburring of undefined edges on CNC machines.

As a result of the great interest shown by visitors to the EMO the pneumatically driven engraflexx AP was modified and launched on the market; this tool was intended primarily for use in robot systems.

The patent for the hydraulically driven (i.e. using the coolant) micropercussion tool was granted just under two years after application was filed.

The scratch marking tool range was developed following the demand from the market for a simpler version of the marking tools.

The first hydraulically operated needle embossing tool for CNC machines was presented as a world first at the tool trade fair in Sinsheim. Only a few months after the official presentation of the needle embossing tools, Daimler was acquired as the first major customer.

After a lengthy development and test phase, the micro percussion tools for CNC machines project was successfully completed. The sales launch took place in spring 1999.